A case study of Ukraine

The reconstruction of Ukraine is an important task for our society. Our future and development prospects depend on the efficiency of its resolution. The effectiveness of this task is grounded in the fundamental engineering solutions that will be selected for its implementation.

To choose a successful engineering concept, it is necessary to formulate the basic requirements for it:

- Closeness to real opportunities and speed. Engineering solutions should meet the capabilities of Ukraine's construction sector and allow speedy implementation and scaling.

- Technological innovation. Modern approaches and ideas shall be at the heart of engineering solutions.

- Flexibility. Engineering solutions should be easily adapted to changes both in the development of the facility and in its operation.

The level of development of the construction sector in Ukraine is very uneven. There are good examples of modern and technological projects, but this is not a widespread phenomenon. Many industries use old technologies and this imposes several limitations on potential engineering solutions. The fastest construction technology among the available technologies in Ukraine is precast concrete, which has the potential for scaling. Its stereotypical name is "panel houses," however, these stereotypes should not interfere with an appropriate assessment of prospects, especially if we pay attention to modern capabilities.

Here are a couple of examples of stereotypes:

"Panel houses" have uncomfortable layout solutions that are impossible to alter.

Nowadays panel houses have changed and they provide more possibilities for architects and designers. One of the main principles of a modern "panel" house is the absence of any bearing structures inside of a residential space.

"Panel houses" have bad thermal and sound insulation.

This is true for the houses that are built based on technologies of the 60s and 70s. However, it does not prevent the construction of energy-efficient and comfortable "panel" houses today in a lot of countries of the world.

These statements can be confirmed by an interesting fact. The market for precast concrete houses has been actively increasing in developed countries of the world during recent decades. It is particularly true for countries where speed and quality are required, such as Sweden and Finland (the latter is a world-renowned technological leader in this field).

So it's essential to find out what are the reasons for such a big difference between perceptions and reality. To do this, let's look at a few examples of identical houses constructed using different technologies.

Technologies of the 60s and 70s

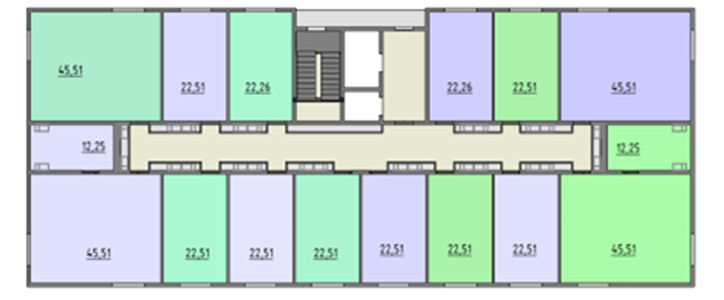

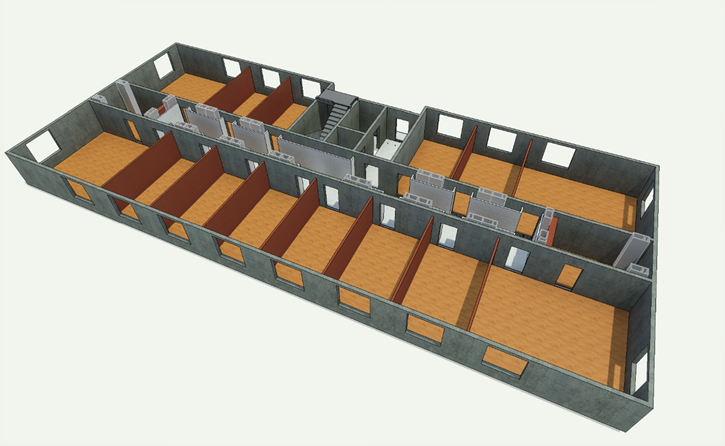

The most widespread design scheme for panel houses of the past years is a design scheme with a narrow step of bearing walls. The distance between the walls is 3,0-4,0 m and reinforced concrete plates with a thickness of 12-16 cm with bad indicators on sound insulation are used as floor slabs.

Modern technologies

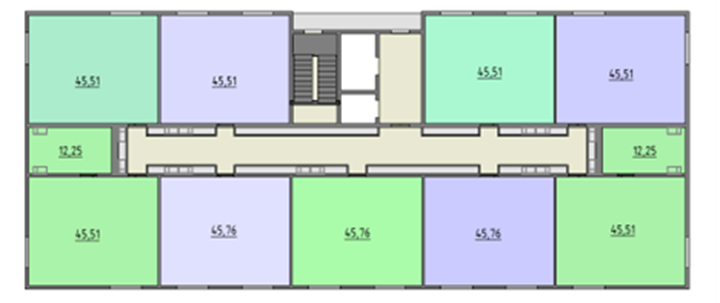

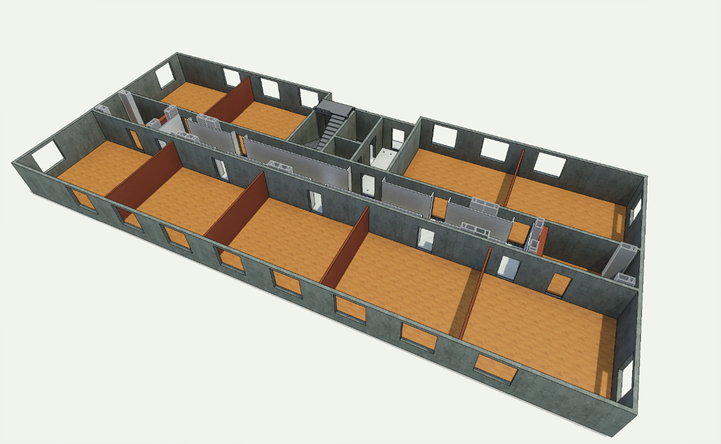

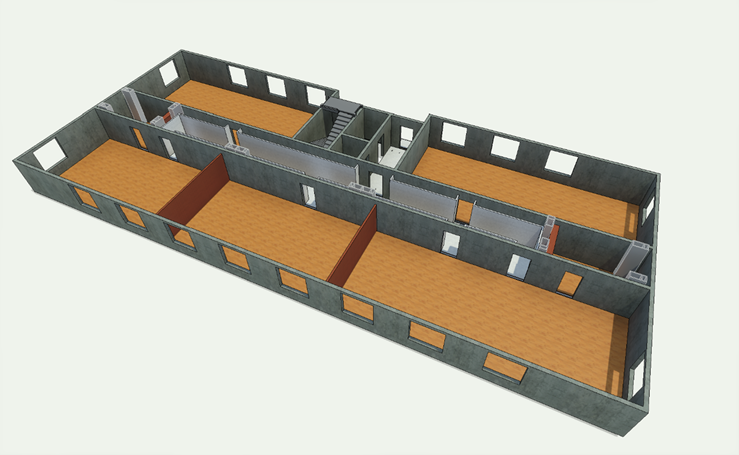

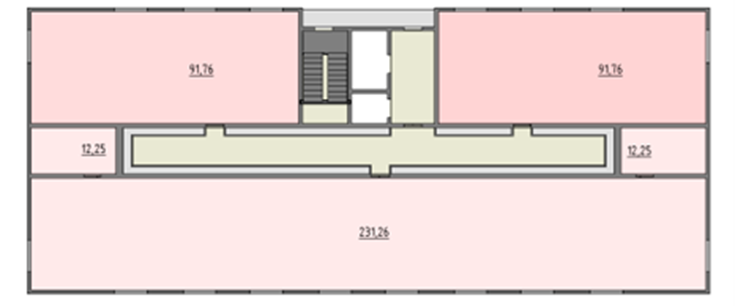

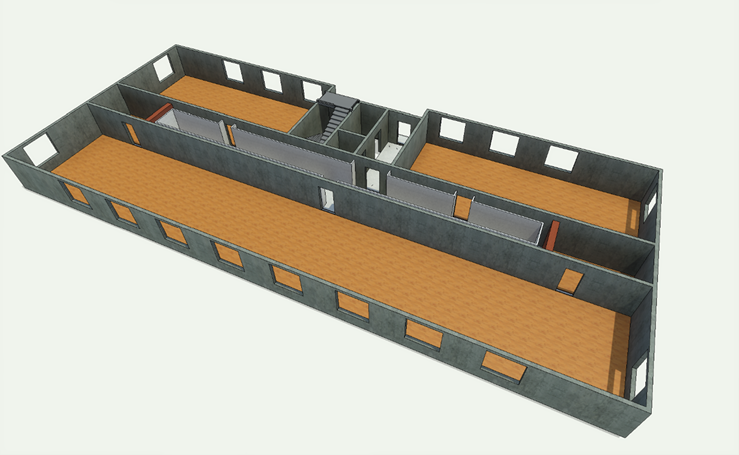

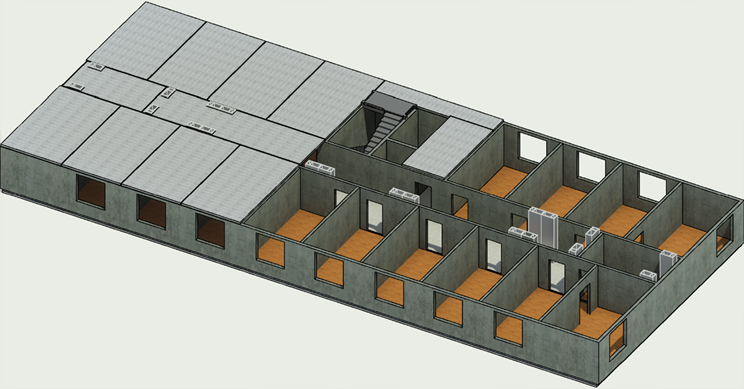

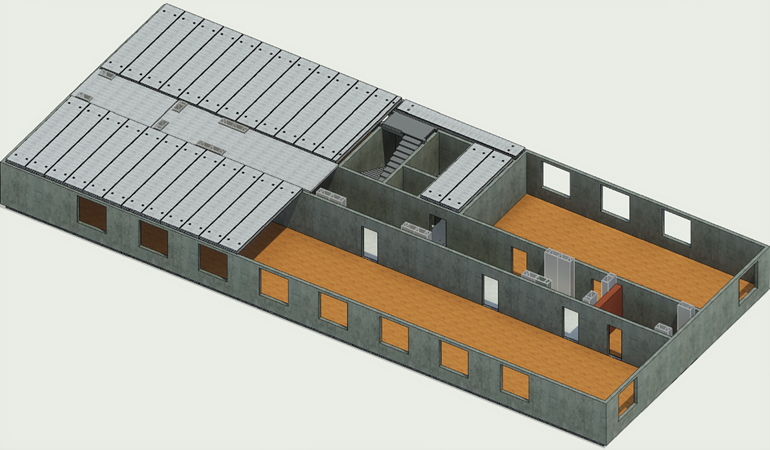

One of the most common modern design schemes is a design scheme with a wide step of bearing walls. The distance between the walls is 6,0-7,0 m, a slab is formed from hollow-core slabs. This scheme enables the formation of a large usable space while using fewer wall panels and reducing the cost of the main structures.

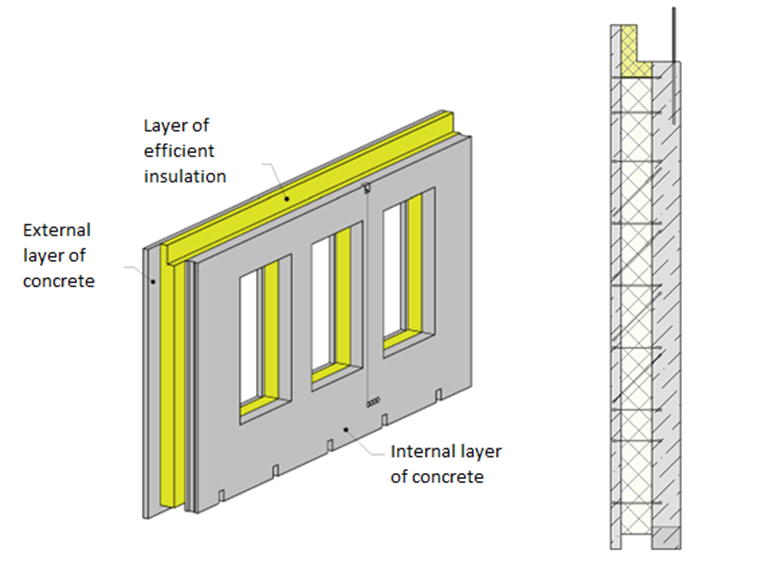

Indicators of the energy efficiency of a house are significantly increased by the usage of wall panels with a layer of insulation inside that enables the development of a long-lasting external layer of concrete and achieves high rates of energy efficiency. Furthermore, due to the usage of composite (non-metal) connecting elements between internal and external layers of concrete, any bridges of cold can be fully excluded. This approach is widespread in countries with cold climates.

High values of sound insulation are achieved by the usage of multi-hollow plates and a structure of floor with sound insulation properties. As a result, the airborne noise insulation index exceeds all modern requirements.

These are only a couple of aspects that clearly show a difference between old and new approaches that appeared as a result of evolution of a precast concrete technology during the latest 50 years. Hopefully, when analyzing possible prospects, these examples will allow us to move from stereotypical to critical thinking.

Looking at the best practices of modern houses a temptation appears to replicate them unchanged, if possible, maybe make them a little cheaper. Unfortunately, such an attempt is doomed to fail because the buildings that we see in Sweden, for example, are built based on individual designs, they are very elaborate, and require a cutting-edge production base and experienced engineering staff. Furthermore, cumulative periods of implementation of such projects from making an investment decision to commissioning last a couple of years, and for us it shall be much faster, preferably for it to take not years but months.